2003 Hundegger Hundegger K2-5

Description

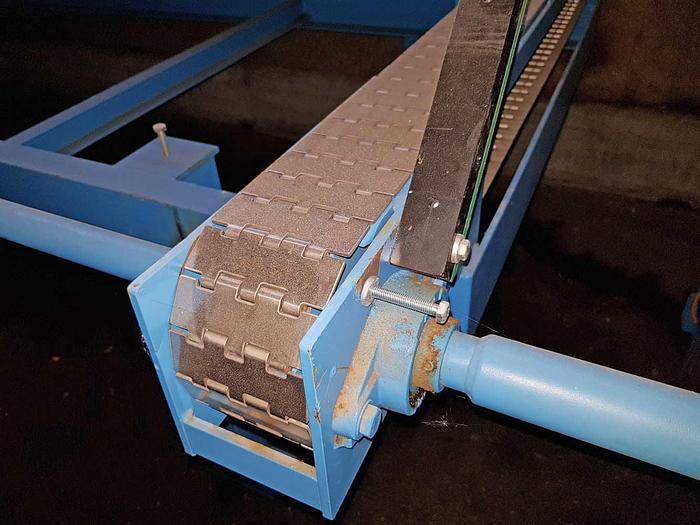

HU N D E G G E R - Joinery line, WORKING CENTRE, model K2-5 From training company Year of constructionHundegger joinery line 2003 Series No. Hundegger: Series No. 11452 Space requirement: Length: 28,2 m Width : 6,5m Height: 2,92 m Total required power: 15 KW 3 x 80 Am. fuses Technical data: This technical specification may contain minor deviations from the actual equipment without affecting the availability of the plant. HUNDEGGER K2 The machine is designed for cross-cutting of workpieces with dimensions of 20 x 60 mm - 300 x 450 mm and an accuracy of +/- 0.1 mm. The machining of the machine includes the machining of almost all connections required in wooden constructions. Production of prefabricated houses and log houses as well as free Combing, profiling and decorating. The machines have fully automatic control and the operator is able to control stacking and conveying at the same time. Cross conveyor belt infeed feed length 2-3 m, stable housing structure with a 40 mm long drive shaft, a motor of 1,5 kW and automatic separation and feeding. The beams are automatically aligned on the cross conveyor belt and fed individually to the machine. Bottom cross saw 360 degrees - One carbide saw blade Ø 735 mm, - Engine power 9.5 kW, 360 ° rotatable and tiltable - Servo hydraulic from 0 - 65 ° and thus enables a cross machining of 570 mm. The saw is hydraulically operated and with fully automatic positioning for work. The saw stroke is controlled according to the cross-section of the wood and the cutting angle. This unit is able to perform all necessary processes, including oblique cuts, longitudinal cuts, straight cuts, etc., as well as the machining of notches to weather plates or the like. The 4-axis control also allows hexagonal sawing. Universal profiling tool - Universal profiling tool 350 x 120 mm, - Tenoning tool 40 x 180 mm and dovetail tool. - The profiling unit has a motor of 11 kW. - 3-axis servo drive ensures precise straight-line design and positioning. - X-axis 550 mm, Y-axis 1400 mm, rotary axis 361 °. - The fourth axis is intended for the conveying and control system of the workpiece. The 4-axis control allows unrestricted working. The Pro filier tool is capable of handling all commercially available wooden joints such as rebate joints, Tail joints, ridge beam joints, notch joints, various tenons, hidden joints, dowel holes, Notches, longitudinal milling, etc. Notching unit For cutting all four sides. The machine consists of two vertical and two horizontal profiling heads with a spindle diameter of 45 mm and a 5.5 kW motor. The The working depth of the cutting tools is set separately by means of a handwheel and digital readout. By using the function of the separate work, the individual machining From one, two or three sides is also possible. The current cutting tools allow notches of max. 210 - 170 mm. Drilling units, 2 pieces The units are equipped with a 2.2 kW motor, a quick-change drill chuck, and a hardened volume head. It allows easy drilling of various blind holes, countersinks, etc. Vertical cutting unit Equipped with a motor of 7,5 kW. Cutting tool 40 x 160 mm. By the use of the combined Vertical support, the device works from below and thus processes the underside. Chain saw unit Motor power 3.0 kW, chain dimensions 8 x 50 x 480 mm Automatic turning station This is a pneumatically operated unit for turning parts through 90 °, 80 ° or 270 °. It allows machining of all sides of the workpiece. Conveying and positioning system Roller conveyor with maintenance-free bearings. Roller size 80 x 500 mm. Position 2 pieces, driven by 4 kW AC servo motor. Automatically optimized speed in the range of 0 - 240 m / min. The positioning uses two independent measuring systems with an accuracy of 0.005 mm. The positioning accuracy to be achieved is +/- 0.1 mm. The detection of the fixed zero points enables a fully automatic movement, even when manufacturing several finished pieces from the same workpiece in fully automatic operation. Consequently, even very short pieces can be machined in a fully automatic operation. The longitudinal control system ensures optimum wood guidance, During processing. Length measuring system The feeding pieces are measured and optimized with a laser. Electronic computer control Dustproof color graphics display, industrial keyboard, and 3 ½ "Drive (Windows based). The operator enters the working dimensions into the computer and the computer calculates the optimum working sequence for each workpiece. The program calculates the Position of each piece for achieving the best accuracy. The fully automatic positioning Allows the complete equipment to work without loss of time. All wood joints are stored in the auxiliary programs and can be imported if required. The calculator provides reports and information on processed pieces, processing times and quantities etc. The data from standard notching programs and CAD programs as well as complete-measurement data (for later calculations) can be transferred to the machine. Entrance table Table with a plastic sliding surface

Specifications

| Manufacturer | Hundegger |

| Model | Hundegger K2-5 |

| Year | 2003 |

| Condition | Used |

| Serial Number | 11452 |