2011 CALDAN A/S Denmark Power and Free overhead conveyor Caldan P&F400

Description

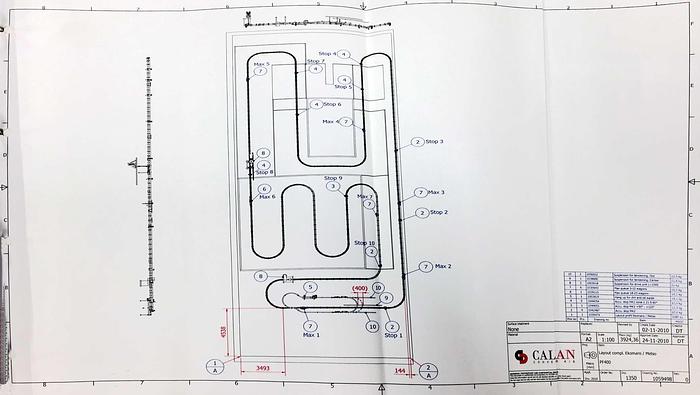

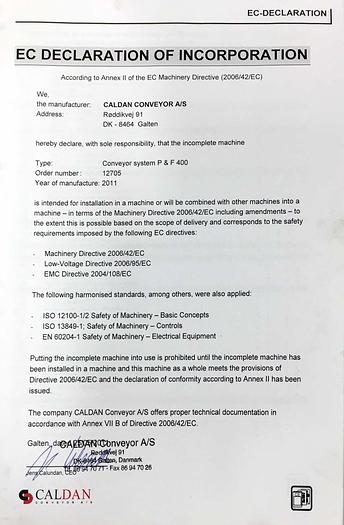

Power and Free overhead conveyor Caldan P&F400 Motorised Rail System Type: P&F 400. Year 2011 Order No 12705 Manufacture CALDAN A/S Denmark Type of chain: Cardan chain. Chain pitch: 270mm. Pusher dog pitch: 1080mm. Wagon type 1: 8 wheeled, 1-ton capacity. Wagon type 2: 16 wheeled, 2-ton capacity. Cycle Time: 15 min. Conveyor speed: 1.5-5 m/min. Operational capacity: 4 wagons per hour. Loading\unloading of parts manually. Rotation type: manual. Features free-standing electrical/control panel Transport: 4 complete trailer Example for similar systems: https://www.youtube.com/watch?v=eHmWHKGRJXc Power & Free overhead conveyor Caldan P&F400 The flexible P&F system with load capacity up to 3.500 kg. Simple and reliable accumulation of wagons in line, 45° and in 90° buffer zones. Smooth trolley transfer from one conveyor circuit to another minimizes the use of transfer units, thus lowering systems costs. Unique trolley- and accumulation stop design ensures an instant and a highly reliable separation of wagons in the accumulating zones. The use of modular components offers total flexibility and liberty in configuring the conveyor circuit layout. Consequent use of tested quality components giving confidence in operation even in very harsh working environments. Noiseless accumulation by means of nonfriction disengagement of the trolleys from the conveyor chain drive. Specifications: The Power & Free conveyor type P&F400 consists of two Caldan straight profiles. In the upper “Power” profile a Cardan chain is driven by one or more drive units. In the underlying “Free” profile the wagons are driven by power chain carriers, via pivotal pawls attached to the front and back of the trolley. Both the chain carrier pitch and the accumulation distance is designed according to customer request. The wagons can, according to handling requirement, be separated and accumulated either inline, or at 45° or 90° within accumulation zones. When routed into a closed accumulation stop, or when reaching the “tail” of the previous trolley, the trolley’s accumulation lever is lifted and the pawl units are lowered. Hereby the trolley is disengaged from the chain carriers. Conveyance with loads in up to 45° rise and fall sections - depending on the load - is possible due to a uniquely constructed link between the chain carriers and the trolley pawls.

Specifications

| Manufacturer | CALDAN A/S Denmark |

| Model | Power and Free overhead conveyor Caldan P&F400 |

| Year | 2011 |

| Condition | Used |